At New England Plastics Corp., we purchase custom compound static dissipative raw resins, produce our own sheet, provide expert engineering and design assistance, design our own tooling, and have the ability to manufacture parts using profile extrusions, rotational molding, vacuum forming and other technologies which best suit our customers' requirements. This enables us to maintain stringent quality and cost controls in vacuum forming the Conductive Tote Boxes featured in this section.

Key Features include:

New England Plastics can also vacuum form, extrude and rotational mold parts from various conductive materials similar to those described here to your specifications. We are a single source plastic manufacturer and would be delighted to provide you with design and prototype development. In addition to extruding our own sheet from raw resins, we provide on-site sonic and induction welding and full fabrication capabilities including CNC routing, punching and stamping.

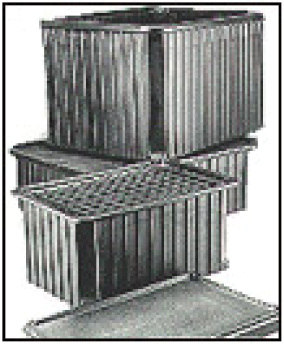

Contact our factory for full details and prompt quotations.Conductive and Anti-static Tote Boxes

New England Plastics' conductive material handling containers allow the safe handling and storage of printed circuit board assemblies, CMOS, MOS components, memory chips, integrated circuits, precision resistors, and other static sensitive components throughout the manufacturing facility.Our standard line includes a wide variety of stackable divider tote boxes, tote and shelf boxes, folio boxes, and ribbed divider tote boxes with adjustable PC board holders, and a complete selection of different style covers for creating a Faraday Cage to shield contents from electrostatic fields. Resistant to most chemicals, solvents, and acids, these rugged, high density polyethylene containers dissipate static charges instantly. If our standard size boxes don't solve your problems, New England Plastics can provide custom boxes manufactured to specific customer requirements.

Conductive and Anti-Static Polyethylene Sheet

The high density conductive polyethylene material which is used for manufacturing Conductive Tote Boxes is available in low and medium density to produce sheet for shelving, covering work and floor surfaces or for vacuum forming your own conductive parts.

Available in sizes up to 4 x 8 ft. sheets or cut to size ranging from 0.030" up to 0.375" thick, this high density conductive polyethylene provides 3,500 psi tensile strength and 2,700 psi compressive strength, Izod impact resistance (notched) is 0.5 ft-lbs./in (min) and density is 1.00 - 1.05 grms/cm3. In addition, some of the low or medium density flexible material can be purchased in rolled form to your specifications.